Infrastructure work towards Rail 200

Posted: 18th May 2025

Work on Horsed Keynes Platforms 1 and 2 nears completion

Work is reaching completion on Horsted Keynes Platforms 1 and 2. In the last month or so, work has concentrated on the platform edge slabs, drainage and the tarmac surface on platform 2 and on the north end of both platforms.

Sorting out the overflowing gutters on Platform 2 led to the discovery of leaks in the underground drainage pipes which was causing dampness in the cellars and required replacement of the rainwater drainage system.

The former model railway room is having a disabled toilet and a unisex toilet fitted. These toilets will be invaluable for special events to save people having to go to another platform.

Some of the stone slabs were loose, others had delaminated and required replacing and there was the remains of an old tarmac surface to be removed. Spare slabs recovered from platform 1 were provided the replacements.

Before replacing the slabs, it was necessary to repair the wall of platform 2. This was in far better condition than platform 1 but there were quite a few loose bricks and also slight subsidence where the culvert runs under the platform but this was nothing like as pronounced as the platform 1 side. The slabs were replaced ensuring that there is a slight backward slope from the platform edge.

At the north end of both platforms, the grass has been removed (it was unpopular with women with high heels) and a flower bed created. The water crane was removed, the stonework around it was replaced making it level with the rest of the platform and at the correct height. The crane was replaced.

With the platform surface work approaching completion, the tarmac surface could be applied.

Preparations to lay the track into platform 1 are well advanced. With the old track long removed, the trackbed has been scraped and levelled, a drain which connects to the culvert put in, terram fibreglass matting laid and ballast spread. The line of the track has been altered to take account of the new profile of platform 1. This has required removing the foot crossing into the field at the north west end of the station.

At the time of writing this, reinstating the foot crossing and compacting the ballast are the only jobs remaining before the track can be relaid.

Left – Martin Whitting and Nigel Chard removing old tarmac from the edge slabs (Jon Goff)

Centre and above right – Drainage work on Platform 2 (Bruce Healey)

Right – The corbelling on platform 2 has been repaired (Tony Astor)

Left – The platform has a temporary surface prior to tarmacking (Bruce Healey).

Centre – The tarmac has been laid round the new base of the water crane (Bruce Healey)

Right – A new beam has been spliced into the canopy structure replacing one which had severely rotted. (Tony Astor)

The trackbed for Platform 1 under preparation (Tony Astor)

A Temporary Replacement for the Wickham Trolley

Posted: 16th February 2025

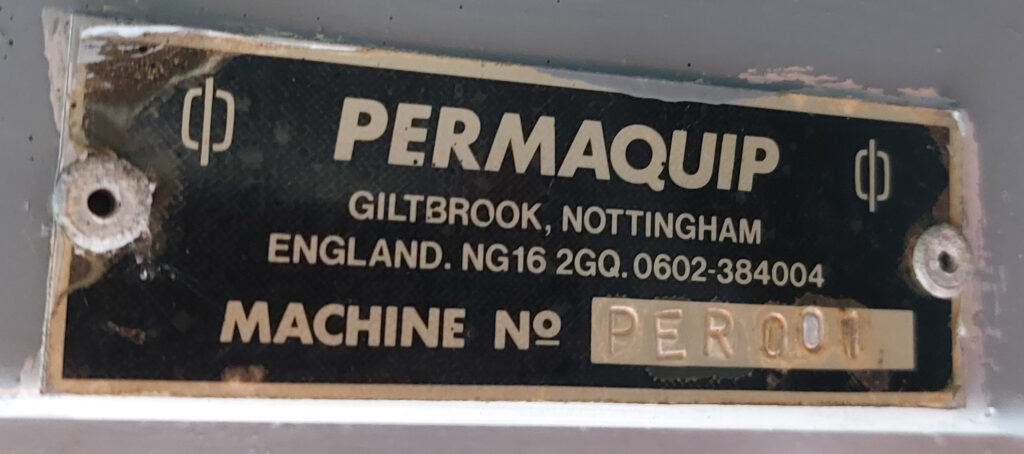

The PermaQuip

The failure of our Wickham trolley with transmission has impacted our ability to carry out maintenance activities. The wickham and trailer were used for transporting tools and all sorts of infrastructure and S&T spares to all parts of the line. The Wickham has been sent away for repairs but with the problem that the non-standard build state is requiring a bespoke solution which is not going to be ready any time soon.

To overcome the problem, and with a dearth of Wickhams available, we have secured the long term loan of a PermaQuip Personnel carrier from the Isle of Wight Steam Railway. A comparison between the Wickham and the PermaQuip gives quite a number of similarities and differences. Both have a driving position at one end but whereas the Wickham can travel as fast backwards as forwards (albeit giving the driver a still neck in reverse), the

To overcome the problem, and with a dearth of Wickhams available, we have secured the long term loan of a PermaQuip Personnel carrier from the Isle of Wight Steam Railway. A comparison between the Wickham and the PermaQuip gives quite a number of similarities and differences. Both have a driving position at one end but whereas the Wickham can travel as fast backwards as forwards (albeit giving the driver a still neck in reverse), the  PermaQuip has a party trick where it can rotate the body of the vehicle. The pirouette is performed by a lift which raises the body clear of the rails, the body can then be pushed round to face the opposite direction.

PermaQuip has a party trick where it can rotate the body of the vehicle. The pirouette is performed by a lift which raises the body clear of the rails, the body can then be pushed round to face the opposite direction.

Although the PermaQuip does have a reverse gear, its maximum reverse speed is walking pace. We do not have a trailer for the PermaQuip and this will severely limit out ability to move equipment and spares around. However the PermaQuip is enclosed giving the personnel a less draughty journey.

Another point of note is that the PermaQuip is the prototype vehicle, serial no #1.

The comment has been made a number of times that in yellow livery, the PermaQuip looks like Peppa Pig’s camper van only on rails. This has led to a plethora of nicknames.

All images: Bruce Healey

Track Relaying in Sharpthorne Tunnel

Posted: 9th February 2025

Track relaying completed

Relaying of the track in Sharpthorne Tunnel has been the first major task of the year for Infrastructure. The wet conditions in the tunnel has caused severe deterioration of the rail although the cast iron chairs were mostly reusable. The wooden sleepers were also mostly in reusable condition so the task was to replace the bullhead rail and change out any bad chairs and sleepers.

Wooden keys had been used in parts of the tunnel which degrade slower than the metal keys in the wet conditions and also provide a good anchor for the rail. The decision was taken to replace them with metal keys. Some of the wooden keys had swollen to such an extent that they were particularly difficult to remove.

As the re-laid track has yet to be tamped, a speed restriction through the tunnel remains.

Cutting a rail and the state of the removed track